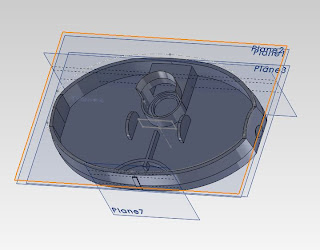

For my final project, it was a challenge one, Making a pump action bottle. It was a bit scary at first when i have to think of how to get all of the parts rgith, because if 1 wrong.......EVERYTHING GO WRONG!

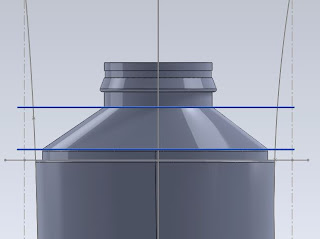

However, the non-cylindrycal bottle was a good excersive for me to get use to create the part using the actual sketches of the bottle and lofting!

the bottle i chosen has a very simple shape, so there were not much trouble creating the loft body.

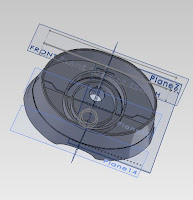

however, making the inside was INSANE! there are totally 9 parts that i need to make seperately and each of them are very difficult to measure becuase there were some very little details, and when i missed, EVERYTHING GONE WRONG! EPICLLY FAIL!

but then finally, im quite happy with what im done for this all excersice! Good start for doing CAD this year and hopefully i can manage to not failing! =.=

and i am excited to look forward to making a computer mouse!! BRING IT ON CAD